|

The Jupiter IDEAL EPS system is a very successful product.

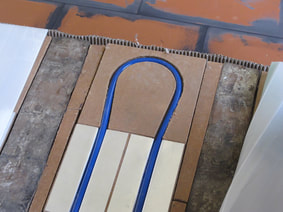

Since its inception in 1996 the system has not changed in design at all. This is testament to good design. The system is a warm water based system which involves 16 mm pipes sitting within insulation panels. The polystyrene panels are manufactured from high density polystyrene and covered with heat emitting aluminium sheet. The aluminium is designed to sit very near to the finished floor which therefore provides responsive and even heat. In the case of installing within suspended timber floors, our system sits snugly between the joists so that the aluminium is flush with the top of the joists. |

|

Jupiter IDEAL ECO is an underfloor heating system manufactured from recycled wood fibre. Being a natural product this system is preferred in old buildings as it allows the floor to breathe. As with the IDEAL EPS system, the IDEAL ECO panels also includes aluminium heat diffuser plates. Aluminium conducts heat very quickly; 4 times more than steel in fact.

Depending on the final floor finishes the heating system can be covered with a variety of surfaces rather than conventional screed. Sand / cement based screed contains lots of water, takes weeks to dry and introduces detrimental moisture into a building. |

|

The Screed Replacement Tile system or SRT as we call it, is unique to Jupiter and we use it cover our heating system instead of screed. The SRT is a 18mm natural ceramic tile that is glued together and is effectively installed as a 'floating' floor. Being ceramic the system has negligible thermal resistance, is ready to use in 36 hours and is exceptionally strong. So strong in fact that you could drive a car over it! The SRT system is suitable for all floor finishes, especially stone and tile floors as we guarantee that the stone or tile floor will never break. We have not had a broken stone floor in our history.

|

|

We have been involved in the reinstating of original timber floor boards over our underfloor heating systems. Of course historic floor boards present problems in their own right. Simply removing them and putting them back down again in the same position is a skilled operation. Timber floors have a considerable thermal resistance and can not be subjected to too much heat as they may distort, cup and shrink. Officially, the maximum temperature that the surface of a timber floor can be is 27C. This represents a mediocre output of 50-60 W/m2 which may not suffice in an old building.

This picture is of original eighteenth century boards that have been reinstated directly on the original joists. The Jupiter heating system is installed between the joists. |

|

Levelling with dry solutions - Levelling Slate

Regarded as an alternative to liquid levelling, our dry levelling slate is a welcome addition to our range of dry building products. Similar to foamed glass but simply a scaled down version, dry levelling slate mechanically binds together and therefore doesn't need additional adhesive or cement. Levelling with sand is no longer regarded as a reliable method as the inherent round structure of sand can lead to dissipation through small unnoticed gaps. Levelling slate can be installed from a minimum of 10 mm to a maximum of approximately 100 mm. Falls within a floor can easily be created by adding a small amount of cement. |